Galvanized 1500 Kg Rubber Torsion Axle with Hydraulic Disc Brake

About torsion axle Torsion axles offer a low-maintenance, reliable, quiet, smooth ride. Mastervim torsion axles make it

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | MITA225011 |

| Tent Type | N/a |

| Axle Number | 1 |

| Tire Number | N/a |

| Color | N/a |

| Condition | New |

| Axle Style | Torsional |

| Capacity | 450 Kgs |

| Width at Hub Face | 90 Inches |

| Mount Width | 74 Inches Outside Brackets |

| Overall Width | 100 Inches |

| Spindle Dimensions | 1-3/8" X 1-1/16" Tapered |

| Replacement | Dexter Axles, Rockwell Axles |

| Manufacturer | Mastervim |

| Transport Package | Pallet |

| Specification | NA |

| Trademark | Mastervim |

| Origin | China |

| HS Code | 87089900 |

| Production Capacity | 1000 Per Month |

Product Description

About torsion axle

Torsion axles offer a low-maintenance, reliable, quiet, smooth ride. Mastervim torsion axles make it simple to have peace of mind while trailer towing.Torsion axles have taken the trailer industry by storm in recent years. The boom in usage can be attributed to the many benefits that torsion axles offer over standard spring axles. Their innovative design provides an array of benefits and avoids many of the shortfalls that have commonly been found in traditional spring axles.

Torsion Axle Benefits

No Maintenance

Torsion axles have a very simple design, using rubber cords and an inner bar, rather than the large array of parts found in a spring axle. The simplicity of this design means that there is little to no maintenance that needs to be done. All you have to do is lube your wheel bearings.Smooth, Quiet Ride

Torsion axles function using a simple design that utilizes the compression of rubber cords inside the axle to cushion the trailer. This twisting and compression motion is very smooth and it rides nicely even when there is no load. Furthermore, there is no metal-to-metal contact inside the axle making it quieter and less abrasive.

Reliable

Torsion axles have fewer moving parts than traditional forms of trailer suspension. As mentioned earlier, there is no metal-to-metal contact within the axles components. This means that there are no abrasive parts rubbing against each other, causing wear or corrosion. Likewise, the rubber construction means that the axles are more corrosion resistant.Versatility

Torsion axles can be used in an extensive range of applications, due to the ease of adjustment. To change the height of a torsion axle, the torsion bars just need to be adjusted. Additionally, half-torsion units can be used, meaning that the application does not need an axle that passes under the entire trailer. This opens up the opportunity for many custom applications and can provide benefits such as additional ground clearance.When is it better than a Spring Axle?

They are particularly advantageous over springs axles for applications like:- Marine/Boat trailers

- Rough/bumpy surfaces

- When much lower or higher ride height is needed

- High vibration applications (like wood chippers or generators)

- Custom applications

- Applications with limited mounting space

- Corrosive environments (like saltwater)

Application

Camper trailer, Fifth-wheel trailer, Off-road trailer, Toy hauler trailer, Double-decker trailer, Caravan towed trailer, Solar trailer, Horse trailer, Jeep trailer, Lowboy trailer, Mobile Home, Pup up trailer, Dolly trailer, Tow dolly, Car hauler, Construction trailer, Genset trailer, Generator trailer, Snowmobile trailer, Boat trailer, Aluminum trailer, Utility trailer, Light duty trailer, etc.

Other products

Rubber Torsion Axle without brakeRubber Torsion Axle with Electric drum brakeRubber Torsion Axle with Mechanical drum brakeRubber Torsion Axle with Mechanical Disc brakeRubber Torsion Axle with Hydraulic drum brakeRubber Torsion Axle with Hydraulic Disc brak

Related ProductCapacity Range

450kg/750kg/1000kg/1250kg/1500kg/1750kg/2000kgs/2500kg/3000kgs/3500kg/4000kg1,650lb/1,750lb/2,500lb/3,500lb/5,200lb/6,000lb/7,000lb /8,000lb

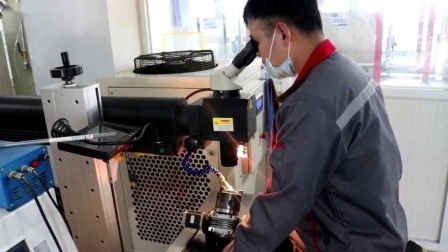

Product Process

Cutting axle tube>welding bracket>welding torsion arm with torsion bar>surface treatment>press rubberWhy choose Mastervim?

Mastervim was established in 2004, as a manufacturer of products for trailers. The product range has varied greatly during our evolution, currently, Mastervim is focusing on developing axles, suspensions, brake parts and other components for the trailer industry.

Our customers represent all types of trailer manufacturers including marine, RV, horse, commercial/industrial, cargo, etc.

Over the past several years, Mastervim has built 5 plants in China, designed several production lines of fully customed parts, involving casting, forging, machining, welding, painting and assembling.

Mastervim is grateful to our OEM customers and suppliers for their trust and support. Please bring your suggestions for improvement to us in our efforts to make a better company. We look forward to serving you in the future.

- Instant Response: 7 x 24 hours online, reply within 3 hours

- Quick Shipping: Big 3 broker partner -MSC COSCO shipping lines, familiar with America AU EU

- OEM Advantages: Unique R&D capability/3D printer Virtua modeling/20 years experience

- Quality Control: Word famous QC system/TUV SGS DOT/Quality guarantee

Related Products